Turnbuckles are some more of those cool fasteners that you've probably seen all your life but may have never noticed. You may have gazed idly at them while stuck in bridge traffic during your commute, or leaned against them while taking a photo at a lookout with a cable railing.

The cool part is that they're not only made to fasten wire together or to anchor it, but they can increase or decrease the tension on that wire.

Key components: a body, and a choice of end fittings

Before we get deep into the weeds of how they work, let's take a look at their different parts. You'll probably find that as you understand the different parts of a turnbuckle, you'll be able to see how they work to adjust the tension of ropes, cables, and other tensioning systems.

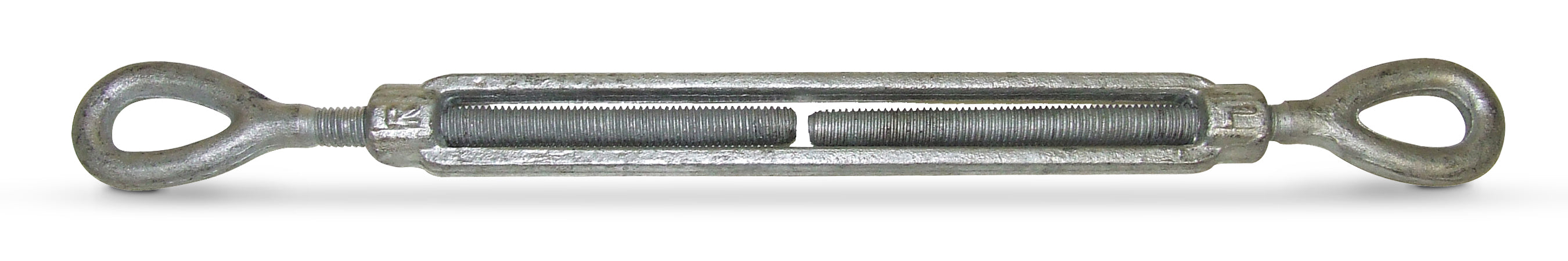

A basic turnbuckle has three different components. There's the body, which is usually open, and then at either end a fitting that can vary depending on its application. These end fittings may be a hook, an eye, or a jaw.

So if you're picturing it, you could have the same end fitting sticking out of each end - for example, two hooks - or you could have a different fitting at each end. You may have a hook at one end, and a jaw, or an eye at the other.

But the magic is in the thread. One end is a standard right-hand thread. The other end, however, is a left-hand thread. This means that as the end fittings are threaded into the body, they get closer together, thereby increasing the tension of whatever cables are being fastened.

Or if you picture the end fittings being held stable, you rotate the body of the turnbuckle to force the end fittings closer together - increasing the tension - and by rotating it in the opposite direction, you'll create more slack in the cables.

Applications, dimensions, and load considerations

You'll find them in all different sizes of course, for their different applications. The size you need likely depends on the load capacity needed and tension that it will be under.

The two key measurements that matter are the thread diameter and the length of the body.

The thread diameter is what determines your load capacity. If your load is 15,000 pounds, you're going to need more than a quarter inch diameter fastener! One point that's important to remember on this score is that thread diameter and cable diameter are not equal: a quarter inch thread has a load capacity of about 500 lb, while a quarter inch six strand wire rope could have a minimum breaking strength of more than 5,000 lbs, and a safe load of more than a thousand pounds.

And the other measurement that matters is the body length. That determines how much slack it can take up. When the end fittings are as far away from each other within the body as possible, the turnbuckle is open, and allows the most slack possible. On the other hand, when the end fittings are tightened as close to each other as they can be, the turnbuckle has taken up as much tension as it can.

Turn buckles are used extensively in boating, bridges, fencing, and construction. They are suited for straight-pull inline uses, and you can attach more than one turnbuckle in a line if you need to take up more slack.

End fittings in turnbuckles

Now a little bit more about the end fittings.

An eye fitting is possibly the most common option. It's used with other components that can open to be attached to it - such as a shackle. The eye does not open and contains no moving parts, and for critical applications, drop forged eye fittings are even stronger than formed and welded ones.

If your cable is going to be attached to a component that cannot open, then you'll likely need to use a jaw end fitting. This type of end fitting has a bolt and nut, which can go through, for example, an eye bolt that it will be anchored to.

Finally, there are hook end fittings. These would typically be used in temporary settings. The reason you don't want this permanent is that accidental slack in the cable could allow the hook to release from its load. On the other hand, they are fast to connect and disconnect, and certainly have uses - consider them in applications like theatrical rigging, where they allow you to quickly change scenery of lighting rigging.

And that's your Where's Waldo challenge for today! How many turnbuckles can you spot in the wild?